The Authorization Chain: How to Stop the "Qualified but Incompetent" Worker

Most safety systems have a fatal flaw. They assume that just because a worker sat in a classroom for four hours, they are ready to operate a piece of heavy machinery.

We call this the "Certification Fallacy."

Having a ticket doesn't mean you have the skill. And it certainly doesn't mean you are authorized to use that specific machine on that specific job.

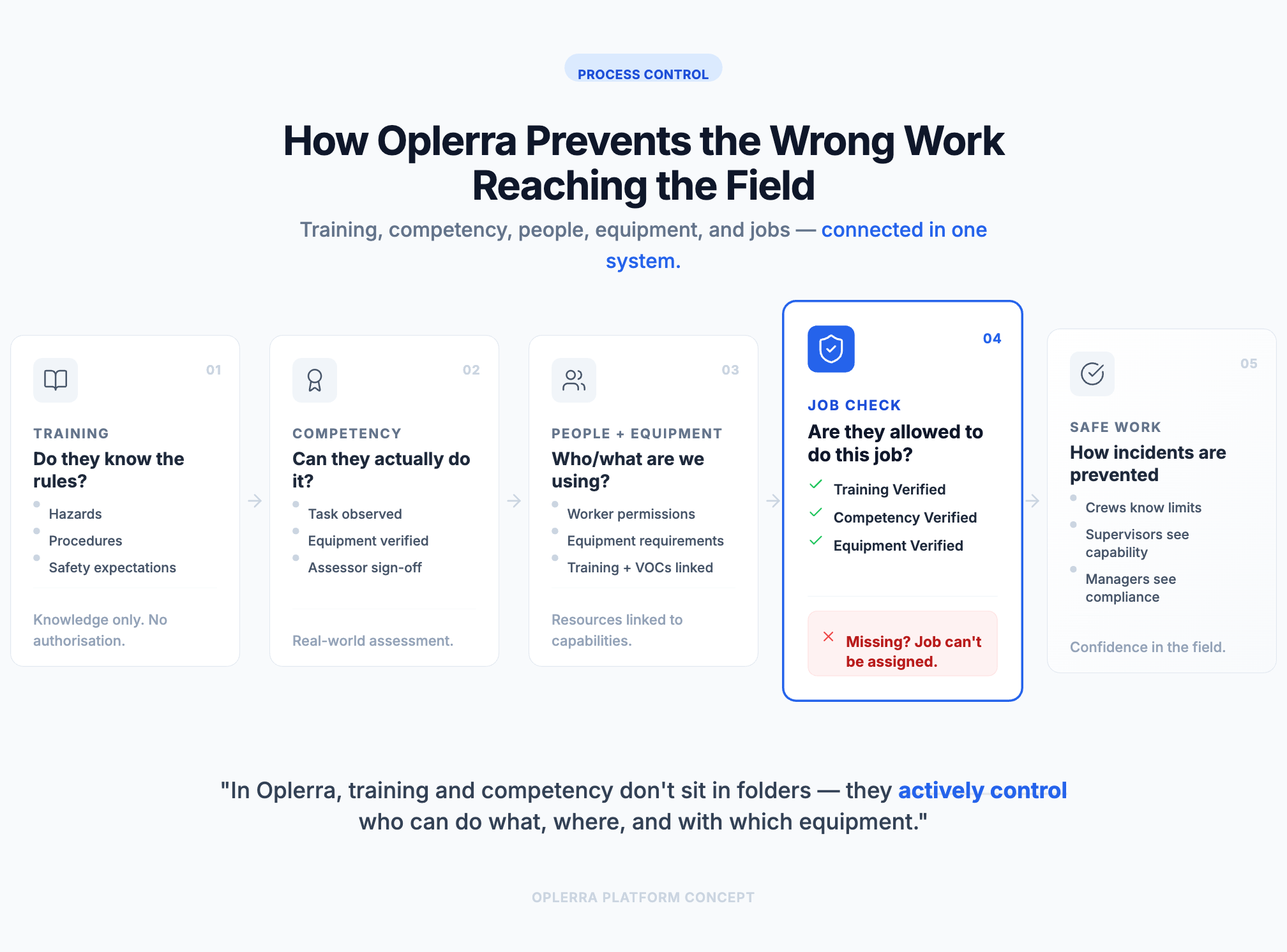

Oplerra moves beyond simple "Training Matrices." We use a 5-step Authorization Chain to ensure that risk never reaches the field.

1. Training (The Theory)

This is the baseline. It’s where workers learn the rules, the hazards, and the theory.

- Examples: Inductions, Electrical Awareness, Chainsaw Theory.

- The Reality: Oplerra tracks this, but we treat it for what it is: Knowledge, not Skill.

- The Rule: Training alone does not authorize work in Oplerra. It just unlocks the ability to be assessed.

2. Competency (The Practice)

This is where Oplerra differs from a standard HR platform. We require proof of execution.

A VOC (Verification of Competency) is a digital form completed by a supervisor in the field. It confirms:

- What specific task was observed?

- What specific equipment was used?

- Who assessed it?

- When does it expire?

It stops the "tick and flick." A supervisor has to put their name on the line to say, "I watched him do this, and he did it safely."

3. The Link: People + Equipment

In the real world, a license isn't generic. A "Chainsaw Ticket" is useless if the worker has never used the specific heavy-duty saw required for today's felling job.

Oplerra creates a hard link between the Asset and the Operator.

- The EWP requires an EWP VOC.

- The Chainsaw requires a Chainsaw VOC.

- The Job requires both.

Everything is connected. You cannot use the tool if you don't have the link.

4. The Gatekeeper: Automated Assignment

This is where the heavy lifting happens.

When a scheduler tries to assign a crew to a job, Oplerra runs an instant background check: 1. Does the worker have the Training? 2. Do they have the current VOC? 3. Does the VOC match the equipment booked for the job?

If the answer is NO: The system blocks the assignment. The job card cannot be issued. The risk is stopped at the desktop, long before the truck leaves the depot.

No arguments. No memory tests. No "I thought he was good to go."

5. The Result: Defensible Safety

When an incident happens, the first thing a regulator asks for is the audit trail.

Most companies scramble to find paper forms. Oplerra presents a unified chain of evidence:

- They were trained.

- They were verified as competent.

- They were authorized for this specific machine.

- They were assigned to this specific job.

Why This Matters

Most systems stop at "They did the course."

Oplerra answers the real questions: Were they competent? Were they authorized? For this job? With this equipment?

That’s the difference between hoping your crew is safe, and knowing they are.